Aluminium housed Resistor are wound with Nickel Copper or Nickel Chromium wire for obtaining required resistance on

a ceramic core fitted with end caps. The winded assembly is then encapsulated in an anodised Heat sink using high

temperature moulding compound.

- Low Cost, Light weight & Compact.

- Non-inductive Type available.

- Custom Values available.

These resistors are applied where high wattage dissipation is required in a small space. The metal heat sink ensures good heat

dispersal & allows a low hot-spot temperature. Major applications include Induction furnace, Medical equipment’s application’s , Humidity chambers etc.

| Power Rating |

5 Watts to 250 Watts |

| Terminations |

Lugs for 5 - 50W , Screws for 100 -

250W |

| Temp Coeff |

± 50 PPM to 200 PPM |

| Tolerance |

± 10%, Closer tolerances

available. |

| Dielectric Voltage |

1000 VAC for 5W & 10W, 1500 VAC

for 25 W & 200W 2000 VAC for 250 W |

| Operating Temp |

-55°C to 250°C |

| Deratings |

Deratings required for reduced chassis

mounted area and for high ambient temperatures. Derate to zero Power

Linearly at 250°C ambient. Derating necessary for unmounted

resistors at ambient temperatures of 25°C, 5W & 10W - 40%,

25W-50% 50W & above 60%. |

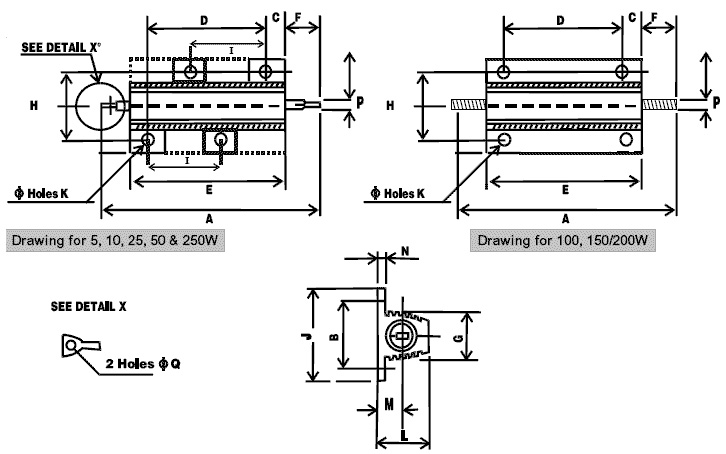

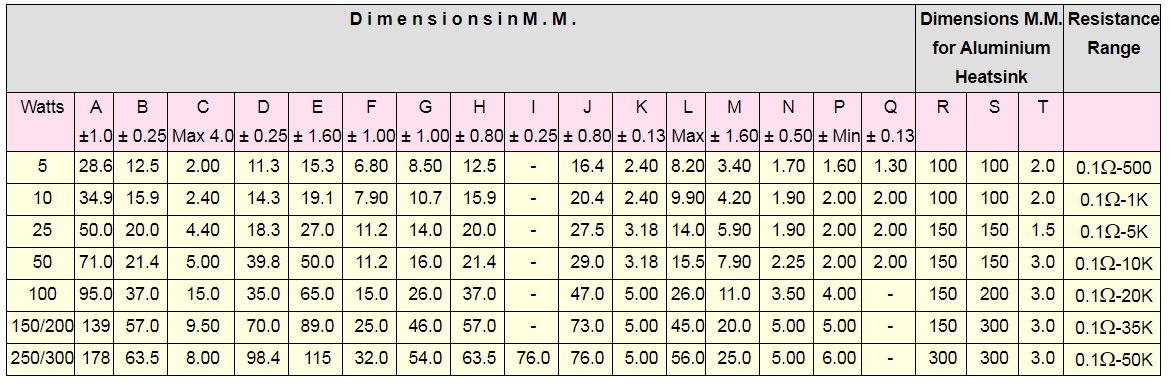

R = Length, S = Width, T = Thickness

value & wattages lower & higher than specified available.

Non - inductive type available.

ORDERING PROCESS/ NOMENCLATURE

ONICS

AHR 50 100R K 0919

ONICS – BRAND NAME

AHR – MODEL NAME

50 – WATTAGE OF THE RESISTOR

100R – RESISTANCE VALUE

K – TOLERANCE +/-10%, IF TOLERANCE +/-5% USES J INSTEAD OF K

09 – MOTH OF MANUFACTURING

19- YEAR OF MANUFACTURING