- Very economical.

- Low temperature coefficient elements for more stable resistance.

- High temperature ceramic core resists shock and vibration.

- With stands severe short time overlaods.

- Reliable terminals.

- Resistors can also be supplied in enclosure.

- Custom built resistors can be made.

- Easy to assemble as a bank.

- Closer tolerance available.

These resistors are used in conjuction with appropriate control equipment to accelerate, dynamic braking of motors.

These resistors are also ideally suited for use in the secondary of AC wound rotor motors for accelerating speed regulating services.

These resistors are also used as neutral grounding resistors. AC and DC dynamic braking load banks, current limiting and blast for mercury vapor lamp

- Very economical.

- Low temperature coefficient elements for more stable resistance.

- High temperature ceramic core resists shock and vibration.

- With stands severe short time overlaods.

- Reliable terminals.

- Resistors can also be supplied in enclosure.

- Custom built resistors can be made.

- Easy to assemble as a bank.

- Closer Tolerance available.

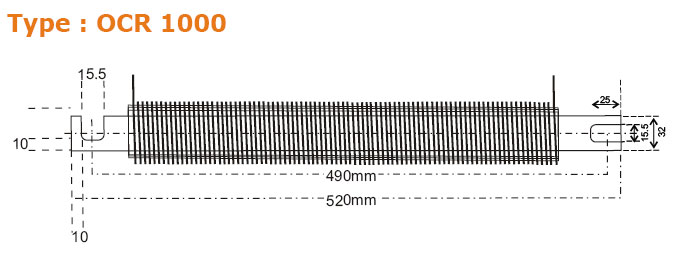

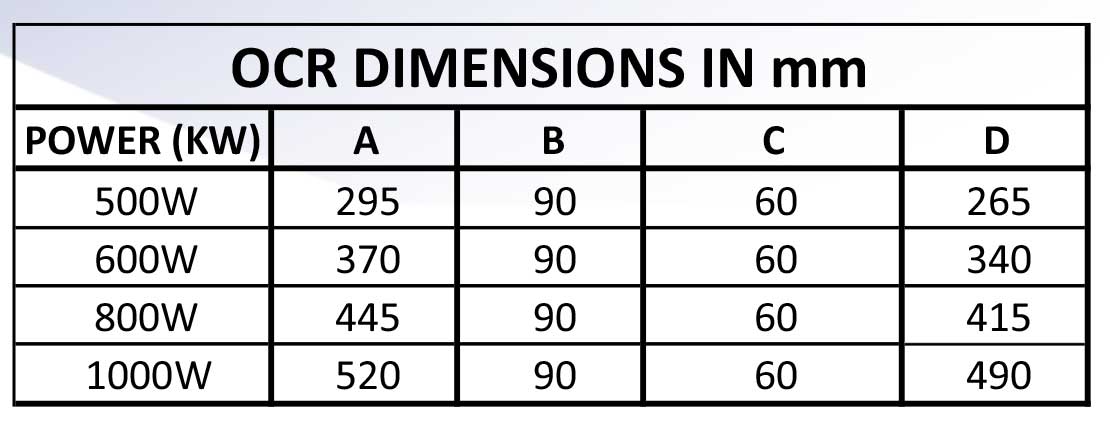

Technical Specifications

- Power Rating: 500W-1KW

- Resistance Tolerance: +/- 10%

- Di-electric Voltage: 2500 VAC

- Insulation Resistance: > 20M Ohm

- Short Term Over Load : 10 x wattage rating for 10 sec

- Temperature Rise: 375 Deg. C + Ambient

- Custom built resistors can be made.

- Safe Operating Temperature 200 Deg. C

- Other Mounting options available.

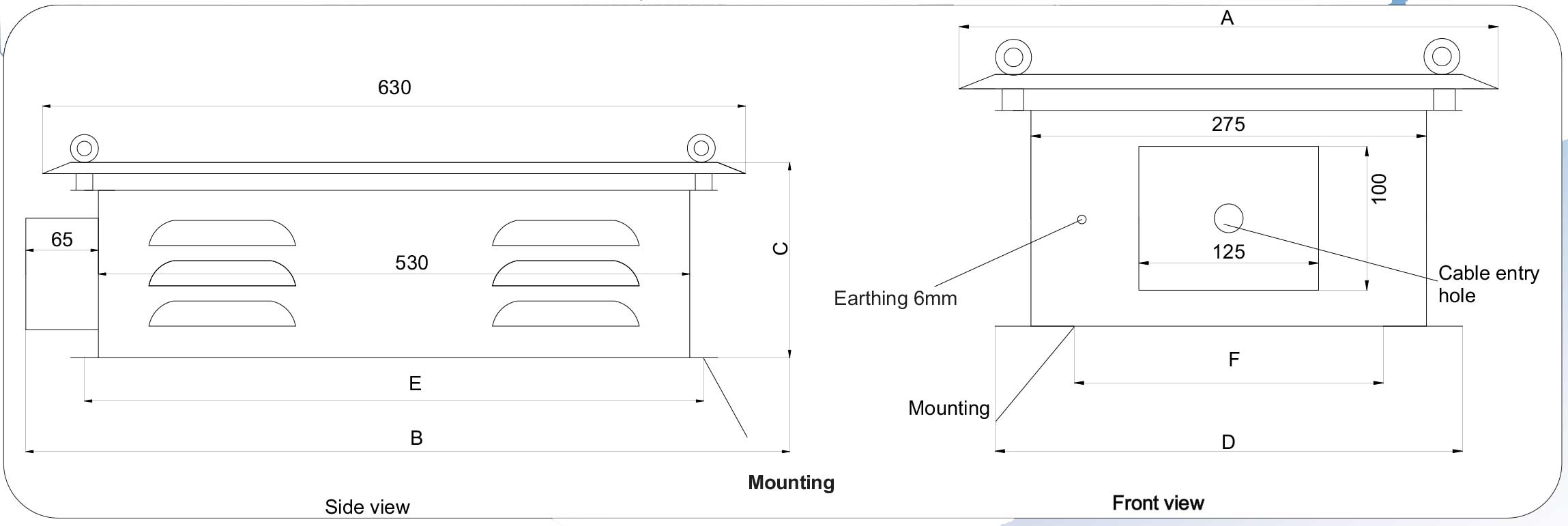

Material Specification

- Enclosure options 2mm, 1.6mm and 1.2mm

- Powder coated or Galvanized Sheet enclosure.

- Resistive material Fecral, Nichrome or Stainless Steel.

- Thermal cutoff 160°C (OPTIONAL)

- Power Connection Copper/Aluminium Bus Bar or connector.

- Protection class available as per requirement.

- Dimensional Tolerance +/- 10mm.

- Custom Design Available.

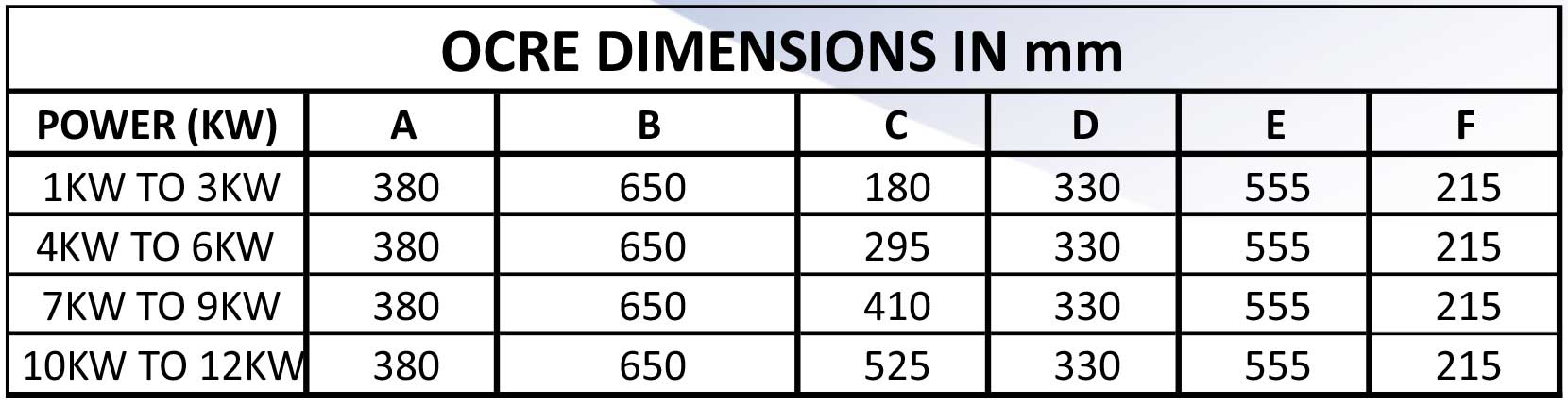

Technical Specifications

- Power Rating: 1-12KW

- Resistance Tolerance: +/- 10%

- Di-electric Voltage: 2500 VAC

- Insulation Resistance: > 20M Ohm

- Short Term Over Load : 10 x wattage rating for 10 sec

- Temperature Rise: 375 Deg. C + Ambient

- Custom built resistors can be made.

- Safe Operating Temperature 200 Deg. C

ORDERING PROCESS/ NOMENCLATURE

ONICS

OCRE5KW 5R K 0619 1234

ONICS - BRAND NAME

OCRE - MODEL NAME

5KW - WATTAGE

5R - RESISTANCE VALUE

K - TOLERANCE +/-10%, IF TOLERANCE +/-5% USES J INSTEAD OF K

06 - MONTH OF MANUFACTURING

19 - YEAR OF MANUFACTURING

1234 - SERIAL NUMBER

Note: If powder coating enclosure required, mention colour shade separately.